1 - Focus on your classic roller ski

Components:

REF: 8501568

Have you just bought a pair of INOVIK CLASSIC ROLLER SKIS and

need to adjust the binding to your shoe size or replace your rollers?

Find our tips here on how to move the binding, maintain and change your rollers or bearings on your roller skis.

Components:

Our INOVIK classic roller skis are sold with a Rottefella binding that can be moved to adjust to your shoe size:

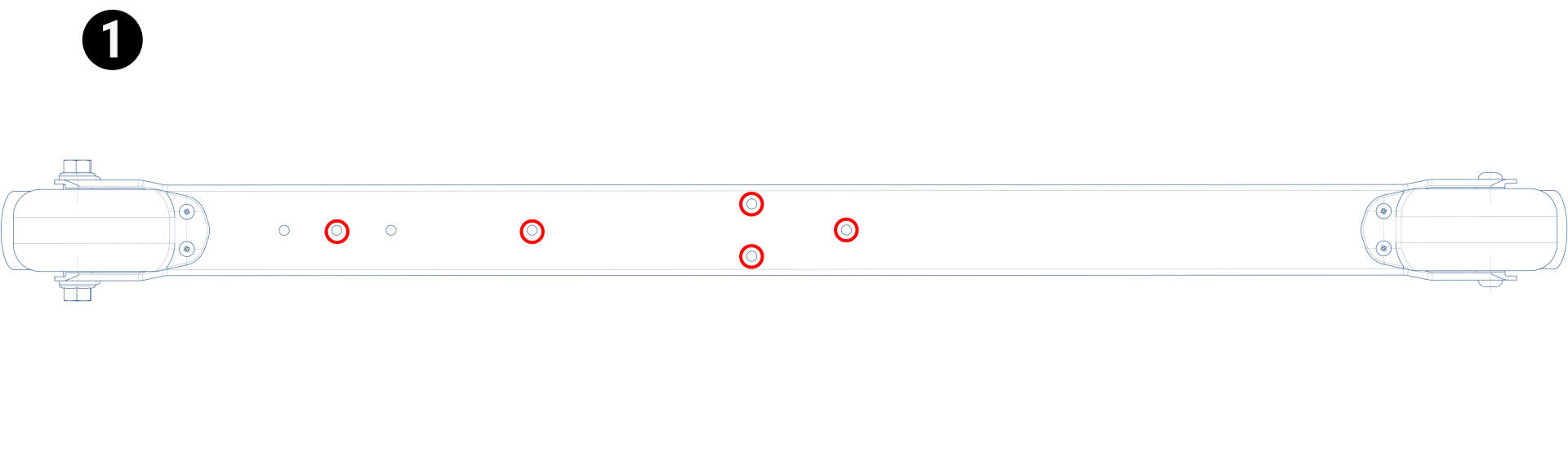

Shoe sizes 7 to 9

Position 1 - standard factory setting

when you purchase your pair of skate roller skis in store or online

Position front binding

on the 7 - 9 position

Position back heel binding

on the 7 - 9 position

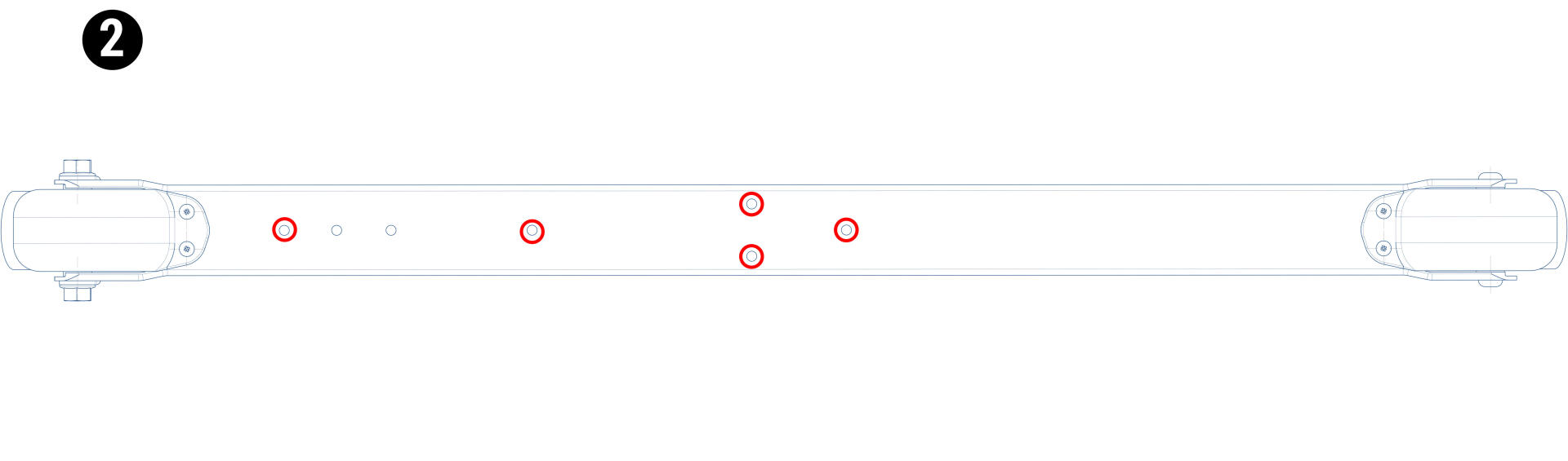

Large sizes from 10-13

Position 2

To adjust the binding to your shoe size:

1 - Keep the front binding position

on 7 - 9

2 - Push the back binding heel backwards

to the 10 - 13 position

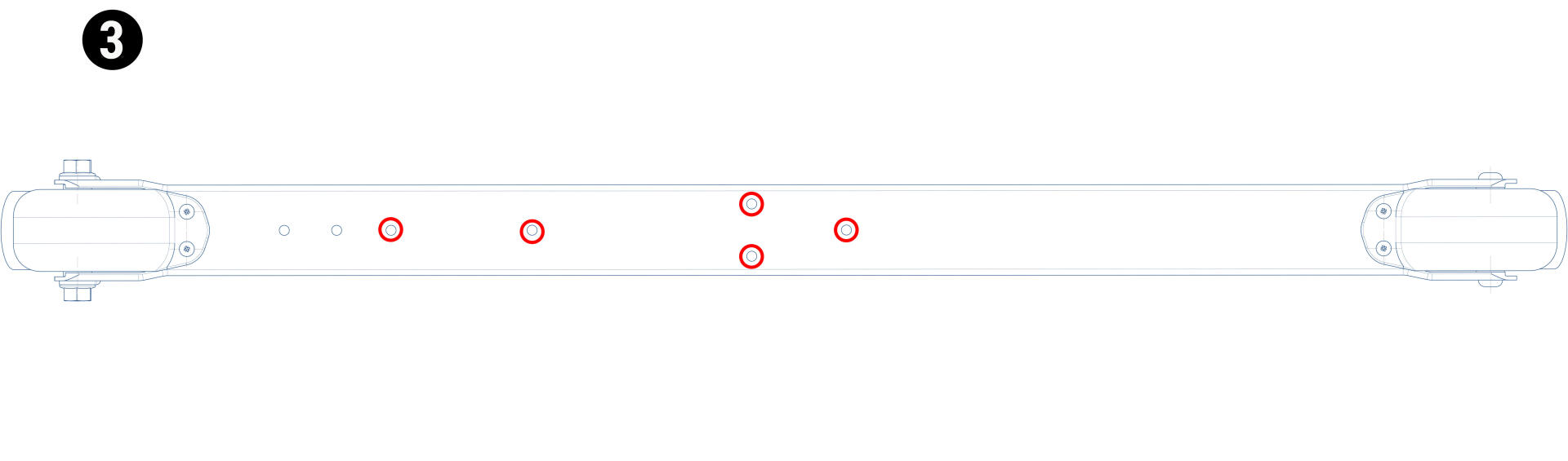

Shoe sizes from 3 to 6

Position 3

To adjust the binding to your shoe size:

1 - Keep the front binding position

on 7 - 9

2 - Push the back binding heel

to the 3 - 6 position

The roller ski frame is pre-drilled so moving the binding is quite easy, however you can always head to your Decathlon workshop for this service.

Time: 5 minutes

Difficulty level: easy

Equipment needed: Bench vice + screwdriver + pozidriv 3 bit

1 - Place your roller ski on the bench vice (you can place a piece of A3 paper folded in 8 around your roller ski beforehand to avoid damaging it).

2 - Remove the screws from the back binding (heel) using a screwdriver with a pozidriv 3 bit

3 - Remove the binding

4 - Reposition the binding and align with the holes for your shoe size (by following the instructions above, namely: push the binding forwards if you want position 3 and backwards if you want position 2)

5 - Replace the screws using a screwdriver with a pozidriv 3 bit

As with all sports equipment, regular maintenance is needed to keep up the performance of your roller skis. You should:

1 - oil your bearings occasionally with a lubricator

and change worn rollers pretty quickly.

Before and after each outing, we recommend you check all screws and bearings thoroughly as well as the state of the rubber on your roller skis!To keep up the performance of your pair of classic roller skis, some regular maintenance of your equipment is important with a few good habits and simple steps:

► Switch the right and left skis regularly to avoid uneven use of the rollers

► After each outing, wipe a cloth over your roller skis and the mudguards to clean and dry them and protect them from rust.

► Oil your bearings occasionally with a lubricator

► Protect your roller skis in a protective case on your trips and for storage.

► Store your roller skis in a dry place

► Regularly check the screws, the rubber on your rollers and the state of the bearings and replace them quickly when worn.

When you buy your roller skis, they come with a classic front roller and an anti-reverse back roller.

The rollers are 100% natural rubber, medium/slow speed - 70 shore A hardness to give a good comfort / lifespan compromise.

The width of the rollers is 46 mm, spacers included, on the classic roller skis 500.

It is important to replace the rollers quickly with new ones once they are worn by choosing rollers from the same brand as your Inovik roller skis.

Changing the rollers is fairly easy to do with a little equipment.

You can do it yourself or entrust this task to a professional by making an appointment in one of our Decathlon workshops.

///

TUTORIAL ON CHANGING THE ANTI-REVERSE ROLLER

► Back roller on classic roller skis

INOVIK CLASSIC ROLLER SKI

TUTORIAL ON CHANGING THE GLIDING ROLLER

► Front roller on classic roller skis

Tutorial based on a skate roller ski (same process)

INOVIK CLASSIC ROLLER SKI

To remove the bearing:

► Lie the roller flat on an open bench vice, slightly wider than the outer diameter of the bearing. (resting on the aluminium rim).

► Insert a screw with a head diameter than fits the bearing hole, ideally a CHC type screw (or one with a fully flat head)

► Tap lightly with a hammer on the end of the screw at a slight angle so that the bearing is driven inside and downwards by the screw head.

Regularly move the screw during the process to balance out the push and so that the bearing comes out parallel to the roller.

Don't hesitate to visit a Decathlon workshop if you can’t manage this step.

Classic roller ski roller

Roller ski bag

Hydration belt